always liked those historical trivia that can be

tossed into a conversation when the talk slows down, so my

curiosity was piqued when I was asked by a friend "Where was

the first commercial oil well?". Well now, I immediately

guessed Texas. Nope. Then I tried Iran. Not there either. Would

you believe Oil Springs, Ontario? I was skeptical so our friends,

Melvyn and Sheila Burrell, both long time residents of the area,

invited us out to see the site of the very first commercial oil

well ever drilled, well actually "dug" in this case.

The next day, Mel and his wife drove us to the outskirts of Oil

Springs, to the Oil Museum of Canada, and for the next several

always liked those historical trivia that can be

tossed into a conversation when the talk slows down, so my

curiosity was piqued when I was asked by a friend "Where was

the first commercial oil well?". Well now, I immediately

guessed Texas. Nope. Then I tried Iran. Not there either. Would

you believe Oil Springs, Ontario? I was skeptical so our friends,

Melvyn and Sheila Burrell, both long time residents of the area,

invited us out to see the site of the very first commercial oil

well ever drilled, well actually "dug" in this case.

The next day, Mel and his wife drove us to the outskirts of Oil

Springs, to the Oil Museum of Canada, and for the next several  hours

we explored the relics and artifacts of a time and business which

is still in operation today. As we stood beside a scale model of

the existing 20,000 barrel per day refinery built in Sarnia in

1958, Mel began his story. So the story goes, long before the

introduction of the automobile, back around the middle of the

1800s, a couple of brothers named Tripp immigrated, looking for

the "gum beds" they had heard about. Gum beds are pools

of oil that have seeped up to the surface. After some

experimentation they were able to boil down the black goo to a

point that it became

hours

we explored the relics and artifacts of a time and business which

is still in operation today. As we stood beside a scale model of

the existing 20,000 barrel per day refinery built in Sarnia in

1958, Mel began his story. So the story goes, long before the

introduction of the automobile, back around the middle of the

1800s, a couple of brothers named Tripp immigrated, looking for

the "gum beds" they had heard about. Gum beds are pools

of oil that have seeped up to the surface. After some

experimentation they were able to boil down the black goo to a

point that it became  asphalt. This was an extremely valuable product

to the ship building world as it is used to waterproof the hulls.

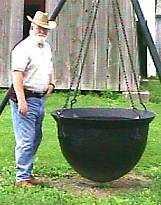

The very first refinery was a large cauldron in which the oil was

heated. It was noted that the lighter kerosene was removed and

sold as a newfangled lighting oil. The work was hard and the

brothers less diligent than was needed to be successful, and

within a year one brother had wandered away and the other sold

his holding to a man named James Miller Williams, who today is

the accepted "Father of the oil Industry". James wasn't

so much interested in asphalt, as he was this new kerosene

product that could be refined from the oil. The market was

growing and demand was outpacing production. Williams abandoned

attempts to recover the surface

asphalt. This was an extremely valuable product

to the ship building world as it is used to waterproof the hulls.

The very first refinery was a large cauldron in which the oil was

heated. It was noted that the lighter kerosene was removed and

sold as a newfangled lighting oil. The work was hard and the

brothers less diligent than was needed to be successful, and

within a year one brother had wandered away and the other sold

his holding to a man named James Miller Williams, who today is

the accepted "Father of the oil Industry". James wasn't

so much interested in asphalt, as he was this new kerosene

product that could be refined from the oil. The market was

growing and demand was outpacing production. Williams abandoned

attempts to recover the surface  oil, electing instead to dig a large pit in the

middle of a "gum bed". At 14 feet he hit free-standing

oil and was soon pumping 50 barrels a day with a hand pump. The

year was 1858 and Williams and his associates had the very first

commercial oil well and refinery, in an oil field which they had

pretty much to themselves. Their exclusive little industry was

short lived as word spread of the "black gold" to be

had for the taking in Oil Springs. Within a year a boom town had

sprung up and thousands were working in the oil industry, buying

land, drilling, pumping or carting off the oil and its

by-products. The secret to this success was a small, simple, but

highly effective mechanical oil pump. It is used today exactly

the way it was in the 1800s. The pump uses an up and down motion

supplied by a walking beam to create a vacuum and suck up small

portions of oil. Two metal pipes are fitted into an outer sleeve

with the lower insert securely fastened to the outer pipe.

Leather washers are attached to the inner pipes to prevent oil

from seeping around. Attached to the end of the lower pipe was a

chamber containing a ball. When the upper pipe is raised, 6 in.

to a foot, a vacuum is created in the chamber. The ball blocks

the upper opening and oil is pulled into the chamber from the

ground. When the pipe goes down, the ball blocks the lower

opening preventing the oil from returning to the ground, and the

only way out is up. Thus a one-way valve is created.

oil, electing instead to dig a large pit in the

middle of a "gum bed". At 14 feet he hit free-standing

oil and was soon pumping 50 barrels a day with a hand pump. The

year was 1858 and Williams and his associates had the very first

commercial oil well and refinery, in an oil field which they had

pretty much to themselves. Their exclusive little industry was

short lived as word spread of the "black gold" to be

had for the taking in Oil Springs. Within a year a boom town had

sprung up and thousands were working in the oil industry, buying

land, drilling, pumping or carting off the oil and its

by-products. The secret to this success was a small, simple, but

highly effective mechanical oil pump. It is used today exactly

the way it was in the 1800s. The pump uses an up and down motion

supplied by a walking beam to create a vacuum and suck up small

portions of oil. Two metal pipes are fitted into an outer sleeve

with the lower insert securely fastened to the outer pipe.

Leather washers are attached to the inner pipes to prevent oil

from seeping around. Attached to the end of the lower pipe was a

chamber containing a ball. When the upper pipe is raised, 6 in.

to a foot, a vacuum is created in the chamber. The ball blocks

the upper opening and oil is pulled into the chamber from the

ground. When the pipe goes down, the ball blocks the lower

opening preventing the oil from returning to the ground, and the

only way out is up. Thus a one-way valve is created.With war looming in the U.S. and the only other well producing oil located in Pennsylvania soon to be shut down, Oil Springs found itself the sole producer of oil in the world, supplying 90 percent of the kerosene in North America. The pits grew deeper

until bedrock

was hit. Not wishing to stop, the ingenious drillers bit through

rock with spring pole drilling rigs powered by two and three men

on a treadle. The drilling rig was an ash pole tree trunk six to

eight inches thick placed parallel to the ground with the heavy

drilling bit suspended from one end of the pole by a chain. As

the men threw their weight forward, the treadle yanked the end of

the pole downward and allowed the cutting tool to strike the

bottom of the well hole. It was about this time that Hugh Nixon

Shaw straggled into town with $50 in his pocket and title to one

acre of ground. Driven by an indomitable will, Shaw began digging

in July 1861. His cash was gone by the time he reached rock at 50

feet down. He raised credit and began drilling further. Month

after month, broke and hungry, his credit having long ago petered

out, he had drilled to a depth of 157 feet into bedrock. Town

folk said he had sweated enough to fill the hole.

until bedrock

was hit. Not wishing to stop, the ingenious drillers bit through

rock with spring pole drilling rigs powered by two and three men

on a treadle. The drilling rig was an ash pole tree trunk six to

eight inches thick placed parallel to the ground with the heavy

drilling bit suspended from one end of the pole by a chain. As

the men threw their weight forward, the treadle yanked the end of

the pole downward and allowed the cutting tool to strike the

bottom of the well hole. It was about this time that Hugh Nixon

Shaw straggled into town with $50 in his pocket and title to one

acre of ground. Driven by an indomitable will, Shaw began digging

in July 1861. His cash was gone by the time he reached rock at 50

feet down. He raised credit and began drilling further. Month

after month, broke and hungry, his credit having long ago petered

out, he had drilled to a depth of 157 feet into bedrock. Town

folk said he had sweated enough to fill the hole.