Bob

was focusing on berry hunting and Ft.Walsh I found a brochure on

the Clay Products Interpretive Centre. We had done many

industries such as; glass blowing factories, an old iron factory

we had never done anything about pottery. The interpretive centre

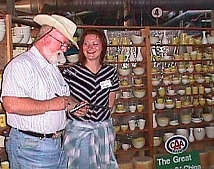

served many purposes. It was a showcase for much of the pottery,

Hycroft China and Sunburst Ceramics that were made in the Medalta

Pottery Factory. They had a catchy way of phrasing it on signs

around town. They said "See the Great Wall of China."

And when we got to the centre we understood why. One of the first

things you see after entering the factory is a large wall

displaying much of the china. Besides being a showcase for the

old china and ware that was made in the factory it allows current

pottery artisans a showcase for some of their work. In addition

they also have demonstrations of craftsmen making pottery in the

way

Bob

was focusing on berry hunting and Ft.Walsh I found a brochure on

the Clay Products Interpretive Centre. We had done many

industries such as; glass blowing factories, an old iron factory

we had never done anything about pottery. The interpretive centre

served many purposes. It was a showcase for much of the pottery,

Hycroft China and Sunburst Ceramics that were made in the Medalta

Pottery Factory. They had a catchy way of phrasing it on signs

around town. They said "See the Great Wall of China."

And when we got to the centre we understood why. One of the first

things you see after entering the factory is a large wall

displaying much of the china. Besides being a showcase for the

old china and ware that was made in the factory it allows current

pottery artisans a showcase for some of their work. In addition

they also have demonstrations of craftsmen making pottery in the

way that was done a century ago.

that was done a century ago. For almost half a century the name "Medalta" ranked as a common word in many Canadian homes. Medalta Potteries of Medicine Hat operated as Western Canada's largest producer of household crockery and hotel china, in the first half of the 20th century, it stood alone in prominence in the Canadian Pottery industry.

The centre was set up with information kiosks at every step providing you with audio information on each area and allowing you to go at your own pace.

Before we went on "the road" I had done some painting on greenware and enjoyed it. But it was interesting to see how they made pottery in the late 1800s to the early 1900s. Surprisingly enough some of the methods they used back then are the same methods they use today, only automated. I actually got to "jigger" a large crock. This is a procedure they use in which they have a mold that is put into a spinning machine. The clay is then put inside the mold (made of plaster) and spun. This causes the clay to spin out towards the inside of the mold. The operator then pulls down a handle that has a large paddle attached. This hollows out

the center of the crock, creating the shape.

The excess clay is forced up to the top and then cut off and

saved for the next piece. Tony Hansen (the jigger operator) was

telling us that during the time of factory, the jigger was one of

the highest paid operators. However, he was paid by the piece. So

he had three people working with him. One would provide him with

the mold, another the clay, and then a third would remove the

piece when

the center of the crock, creating the shape.

The excess clay is forced up to the top and then cut off and

saved for the next piece. Tony Hansen (the jigger operator) was

telling us that during the time of factory, the jigger was one of

the highest paid operators. However, he was paid by the piece. So

he had three people working with him. One would provide him with

the mold, another the clay, and then a third would remove the

piece when it was done. After the piece was finished it

dried inside the mold. So they had to have hundreds of molds on

hand. As the piece dried it pulled away from the inside of the

mold allowing it to be removed, and then dried further. Finally

it could be decorated or simply left plain and then glazed and

fired. Unfortunately the advent of plastics took a big bite out

of the pottery industry. There are still factories that

specialize in fine china but there isn't a big demand for the

large crocks that were once used for storage of everything from

flour,

it was done. After the piece was finished it

dried inside the mold. So they had to have hundreds of molds on

hand. As the piece dried it pulled away from the inside of the

mold allowing it to be removed, and then dried further. Finally

it could be decorated or simply left plain and then glazed and

fired. Unfortunately the advent of plastics took a big bite out

of the pottery industry. There are still factories that

specialize in fine china but there isn't a big demand for the

large crocks that were once used for storage of everything from

flour, to sauerkraut, to cream. I did find out that the fine bone china

that is still made today still use lead in their designs, because

they can get a much brighter color with the lead paint. However,

in most cases with the fine bone china there is not enough lead

to be harmful to humans. We met Zarnab, a lovely 16 year old

young lady, that was there on a program from her high school that

was free-hand drawing a design on one of the bowls made there. I

certainly hope that she continues in art, as she was very good at

it.

to sauerkraut, to cream. I did find out that the fine bone china

that is still made today still use lead in their designs, because

they can get a much brighter color with the lead paint. However,

in most cases with the fine bone china there is not enough lead

to be harmful to humans. We met Zarnab, a lovely 16 year old

young lady, that was there on a program from her high school that

was free-hand drawing a design on one of the bowls made there. I

certainly hope that she continues in art, as she was very good at

it. If you visit be sure and see their 2nd site located just down the street. This site features several of their outside or beehive kilns which were used in the very early years, plus a large historic building with many more pottery displays. For more information or their hours call: 403-529-1070 or check out their website at: Medicine Hat Clay Industries.