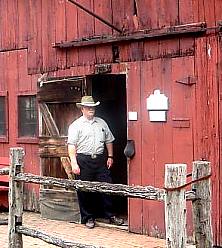

Historic  roscoe Village, located on the west side of Coshocton, is now a

combination of trendy shops and old time crafts buildings. We stopped by

the visitor's center and went through their small museum. This is where I

got most of my knowledge of the canals. There were also some antiques as

well as many things for kids to handle. Laura found a miniature loom and

ran a couple of bobbins through the stings. The main street was

lined with clapboard cottages, along red brick sidewalks. Shade trees

offered shelter for the many benches that sat along the walk. Every other

house or so had a sidewalk that ran between it and the next house. These

stairways and paths led to

roscoe Village, located on the west side of Coshocton, is now a

combination of trendy shops and old time crafts buildings. We stopped by

the visitor's center and went through their small museum. This is where I

got most of my knowledge of the canals. There were also some antiques as

well as many things for kids to handle. Laura found a miniature loom and

ran a couple of bobbins through the stings. The main street was

lined with clapboard cottages, along red brick sidewalks. Shade trees

offered shelter for the many benches that sat along the walk. Every other

house or so had a sidewalk that ran between it and the next house. These

stairways and paths led to  yet more shops and crafts. Around every corner

was yet another surprise. It was all quite enchanting. We

considered our time constraints and decided to forgo the trendy shops for more

time with the crafts. Our first stop was at the blacksmith's. This

was one of the first cottage industries to appear along the canal. There

were many iron parts required to keep canal boats and the canals themselves in

working order. The blacksmith we met was both talented and

entertaining. He explained in detail how a nail was made before the industrial

era. As he drew out a "nailrod" from which the nail was made, he

heated it to a red hot glow. He then banged on it for a while before heating

it again. This time he added a vertical edge to the anvil and

laying the heated rod over the edge gave it a couple of solid hits, causing a

wide grove to appear. Bending

yet more shops and crafts. Around every corner

was yet another surprise. It was all quite enchanting. We

considered our time constraints and decided to forgo the trendy shops for more

time with the crafts. Our first stop was at the blacksmith's. This

was one of the first cottage industries to appear along the canal. There

were many iron parts required to keep canal boats and the canals themselves in

working order. The blacksmith we met was both talented and

entertaining. He explained in detail how a nail was made before the industrial

era. As he drew out a "nailrod" from which the nail was made, he

heated it to a red hot glow. He then banged on it for a while before heating

it again. This time he added a vertical edge to the anvil and

laying the heated rod over the edge gave it a couple of solid hits, causing a

wide grove to appear. Bending it back and forth at the grove caused the

end of the nailrod to break off, creating the nail. One quick grasp by a

vice and a few solid hits on the large end, and a head appeared. The nail

was done. This job was often delegated to a new apprentice who would

sweep up the iron scrap melt it down and draw it out into a nailrod.

it back and forth at the grove caused the

end of the nailrod to break off, creating the nail. One quick grasp by a

vice and a few solid hits on the large end, and a head appeared. The nail

was done. This job was often delegated to a new apprentice who would

sweep up the iron scrap melt it down and draw it out into a nailrod.

Next we stopped by the cooper's shop for a lesson on bucket making. This

craft disappeared as a trade many years ago. It was an exacting trade that

took many years of apprenticeship to learn. It started with learning the

different properties of the various woods. The trick with buckets was that

they generally had to be water tight. Our cooper had many different types

of wood for us to handle. His buckets were made out of woods that would

swell when wet, as they did not use glues or interlocking of the wood

pieces. Pressure alone kept the water in. He explained that if not used

for a while they often did leak when first filled up. This would end as the

wood swelled and the pieces tried to expand against the rings that held them in

place. The pieces came from split logs which were then shaped with a

drawing knife while the wood was held fast on a shaving bench which he usually

made himself. In earlier times, the buckets were held in place with wooden

rings, as metal was too expensive. The wood rings were shaved thin and then

steamed so they would bend. An ingenious locking design allowed the ends

to lace into each other and still lay flat along the bucket's

were made out of woods that would

swell when wet, as they did not use glues or interlocking of the wood

pieces. Pressure alone kept the water in. He explained that if not used

for a while they often did leak when first filled up. This would end as the

wood swelled and the pieces tried to expand against the rings that held them in

place. The pieces came from split logs which were then shaped with a

drawing knife while the wood was held fast on a shaving bench which he usually

made himself. In earlier times, the buckets were held in place with wooden

rings, as metal was too expensive. The wood rings were shaved thin and then

steamed so they would bend. An ingenious locking design allowed the ends

to lace into each other and still lay flat along the bucket's  side.

side.

There were many other crafts being demonstrated along the main walk. We

visited a broom maker, soap maker and candle maker. There was also a log

cabin-type bedroom with a docent who talked about life on a early Ohio farm,

before electricity or trains. We were still going strong with several

other places to visit when the bewitching hour of 5:00PM struck and the town

seemed to fold into itself. Windows closed, doors locked and docents were

nowhere to be found. It was a wonderful time and those who spoke to us

made it all seem to be so much fun to live 150 years ago.

*** THE END ***